Folding screen design breaks through the bottleneck of mobile phone screen size, flexible OLED components face innovation

Date:

2020-11-02

The realization of "foldable" flexible OLED components faces innovation. After the "full screen" iteration, the mobile phone screen continues to increase and has encountered a bottleneck. After the latest round of full-screen iterations, the screen-to-body ratio of mainstream flagship models is generally above 85%, and the room for improvement is very limited, and the body size is generally around 7 inches, which has already challenged portability and the limit of operability. Therefore, at present, if the original product form design is still used, there is almost no room for improvement in the size of the mobile phone screen.

The realization of "foldable" flexible OLED components faces innovation. After the "full screen" iteration, the mobile phone screen continues to increase and has encountered a bottleneck. After the latest round of full-screen iterations, the screen-to-body ratio of mainstream flagship models is generally above 85%, and the room for improvement is very limited, and the body size is generally around 7 inches, which has already challenged portability and the limit of operability. Therefore, at present, if the original product form design is still used, there is almost no room for improvement in the size of the mobile phone screen.

Breaking the original product form, the folding screen design can continue to increase the screen size of mobile phones. The "folding screen" design uses a large-area flexible foldable OLED screen, which is divided into two forms: "inward folding" and "outward folding", allowing consumers to obtain a dual experience of tablet computers and mobile phones. Due to the high technical difficulty, there is currently no mature "folding screen" mobile phone product on the market, but we have observed that major manufacturers (such as Samsung, Huawei, OPPO, Xiaomi and Apple) have increased their layout in this direction. .

Since the "folding screen" design can break through the bottleneck of the existing mobile phone screen size, it can theoretically continue to double the screen area of the existing mobile phone, and the portability of the product will not be affected by the foldable form, so we believe that along the The main line of screen size continues to increase, and folding screen design will be a clearer next-generation development direction for smartphone products.

In addition to the mobile phone that everyone is concerned about, LG's newly released rollable TV brings a new design concept to high-end TV products, breaking the original fixed form of TV, allowing the TV to adjust the screen size and display ratio according to the usage scene. , and endows the TV with movable functions, using flexible OLED display technology in addition to the original iterative directions such as 8K and ultra-large size to open up another development idea for TV products. We believe that, based on the rollable design, flexible OLEDs are expected to be applied in large-scale applications in the future, and 2019 will also be the first year of large-scale flexible displays.

By using flexible PI film for packaging, OLED can be made into a flexible OLED panel with folding function. At present, it will become the only screen solution for folding screen. Under the combined effect of demand explosion and price drop, the demand for flexible OLED panels will grow significantly. Mainland panel companies have invested in flexible OLED production lines on a large scale in the past two years. Many production lines have achieved mass production, and the production capacity and yield have been ramping up smoothly. They already have strong strength in this field.

除柔性OLED面板外,相较于原有普通的直面(例如iPhone X)或是固定曲面(例如GalaxyS9)形态的柔性OLED屏幕,“可折叠”OLED屏幕有多处环节发生了重大变化,其中最关键的几处在于盖板方案、OCA胶和偏光片,这些环节的新变化为产业链相关企业带来价值量提升。

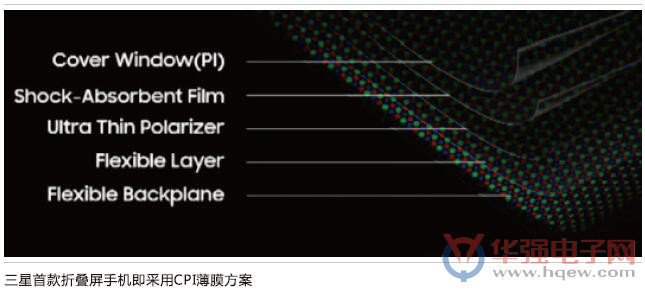

盖板方案:CPI薄膜替代玻璃盖板

The current mobile phone screen cover solutions are all made of glass material. Although the dynamic bending function can be achieved after reducing the glass thickness to a certain extent, it does not support repeated folding with a small radius and is very fragile. Therefore, the solution of folding the screen cover It needs to be realized by polymer film.

Since the polymer film generally lacks sufficient surface hardness, a hard coating needs to be made on the surface of the polymer film to achieve scratch resistance and a good touch like glass. The production of hard coatings generally needs to be carried out in a high temperature environment (such as thermal spraying, thermal evaporation and other processes), so there are strong requirements for the high temperature resistance of the film. In addition to high temperature resistance, in order not to affect the display effect of the screen, there are also high requirements for the transmittance of the film.

Based on the above performance requirements, a plastic colorless polyimide (CPI) film with flexible properties is expected to become an ideal cover material for folding screens. The thermal expansion coefficient and cost of CPI are higher than those of glass, but the heat resistance is better than that of other plastic materials such as polyethylene terephthalate (PET) and polycarbonate (PC). Meet flexibility and strength requirements. When manufacturing CPI, a hard coating process with a thickness of tens of microns is required on the surface, such as the use of mixed material siloxane, which is expected to make the CPI feel close to glass and improve the strength of the CPI.

At present, the manufacturers with CPI film mass production capacity mainly include South Korea's Cologne Industry, Japan's Sumitomo Chemical, South Korea's SKC and other manufacturers. According to DIGITIMES Research, South Korea's Cologne Industrial Co., Ltd. has a fast pace in deploying CPI films, and has started trial production in the first half of 2018. SKC is scheduled to complete the construction of mass production equipment for CPI films in the third quarter of 2019. At the same time, South Korea's LG Chemical also intends to invest in the CPI film industry.

At present, the manufacturers with the production capacity of folding screen CPI cover are mainly South Korea's Kolon Industries (Kolon Industries), Japan's Sumitomo Chemical (Sumitomo) and South Korea's SKC three major material manufacturers, and LG Chemical (LGChemistry) is also accelerating investment, is expected to be in 2019. annual supply capacity. According to Digitimes, Samsung's upcoming first foldable phone uses Sumitomo Chemical's solution.

OCA glue: It can withstand folding without falling off, and the technical difficulty is greatly improved

OCA (Optically Clear Adhesive) glue is a component bonding material used in the manufacture of panel modules. The OCA glue used in the folding screen must withstand more than 200,000 bending times without affecting its function. It needs to have a certain degree of liquidity while maintaining viscosity, so the technical difficulty is greatly increased compared to the past.

At present, 3M in the United States, Samsung SDI in South Korea and Mitsubishi in Japan are the main suppliers of OCA glue for folding screens. According to Digitimes, the OCA glue used in Samsung's first foldable phone is exclusively supplied by Samsung SDI.

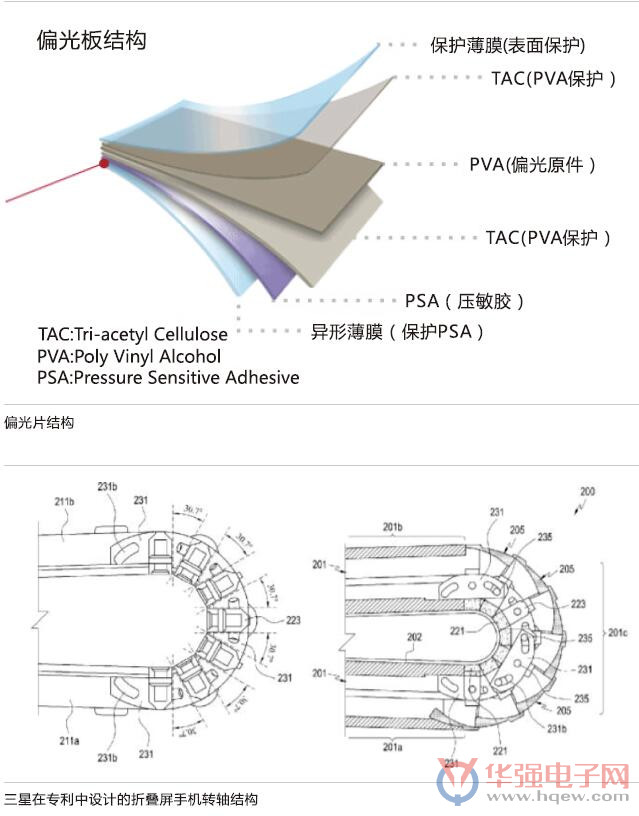

Polarizers: Requires a substantial reduction in thickness

In terms of polarizer production process, the traditional production process is coating composite process, that is, PVA film, TAC film, compensation film and other film materials are composited with a coating process to obtain polarizer film. This process is characterized by mature technology and high yield. High, but the disadvantage is that the polarizer produced is relatively late, so the flexible display is obviously disadvantaged. With the increasing demand for flexible displays, the new process of flexible polarizers will be an important trend, among which the liquid crystal coating process is an important aspect at present.

Due to the consideration of mechanical design, in order to realize the foldable function, the thickness of the OLED screen module must be reduced as much as possible. Therefore, the thickness of the polarizer used in the folding screen needs to be greatly reduced, which puts forward higher requirements for the process. Samsung disclosed at its SDC conference in November 2018 that in its upcoming folding screen mobile phone products, the thickness of the polarizer has been reduced by 45% compared to the past.

At present, Nitto Denko and Sumitomo Chemical have the production capacity of high-end ultra-thin polarizers. According to Digitimes, Samsung released its first foldable phone using a solution from Nitto Denko.

Rotating shaft: It needs to withstand tens of thousands of bends, and the MIM process is expected to shine

Under the design of the folding screen, the thickness of the folded mobile phone body will inevitably increase compared with the current smartphone products, which may affect the user experience of consumers. In this context, mobile phone manufacturers will try their best to use new materials and new solutions to reduce the thickness of the fuselage. The folding shaft is an important link that affects the thickness of the fuselage. It is expected to use high-elasticity and high-strength liquid metal as the material solution. There is a high probability that the board will return to the all-metal solution from the currently popular glass solution.

In terms of the hinge, the hinge must ensure that the foldable mobile phone maintains a certain R angle after being folded, and it must remain flat after opening, and it needs to withstand more than 100,000 folding tests, which is very difficult to develop.

MIM metal powder molding is a process that focuses on the processing and manufacturing of complex precision metal parts, which has relatively great advantages for the processing of micro-precision structural parts. The hinge shaft of the folding screen has high requirements on precision and strength, and the complex structure and size are just within the advantageous range of the MIM process.

At present, a variety of shaft products using the MIM process have been mass-produced. The 2-in-1 keyboard hinge of Huawei MateBook E uses high-precision MIM. The hinge has a wire cutting process with a precision of 1.01mm and a 160° highly damped hinge, which breaks through the limitation of the fixed support angle of traditional 2-in-1 notebooks.

At present, manufacturers that can mass-produce rotating shafts include Changying Precision, Qihong Technology, South Korea's Diabell, Amphenol, Foxconn, BYD and other companies. According to Digitimes reports, the hinge of the first folding screen mobile phone released by Samsung is in charge of the Korean factory KHVatec. The hinge may adopt a gear structure, but there is no public information on the specific content of the plan.

Japanese and Korean manufacturers dominate the Galaxy Fold supply chain, and domestic manufacturers also have layouts

We have sorted out the key links in the supply chain of Samsung Galaxy Fold, other mature suppliers in the industry chain, and domestic manufacturers with corresponding layouts as follows:

(1) Panel manufacturing: Samsung Galaxy Fold uses the "Infinity Flex Display" foldable OLED screen produced by its own SDC. Other mature suppliers in the industry chain include South Korea's LGD, Taiwan's AUO, and domestic leaders in flexible OLED layout BOE and Visionox.

(2) Touch layer: Samsung Galaxy Fold uses On-Cell's Y-OCTA touch solution (Metal Mesh electrode material) to complete the touch layer in the OLED panel manufacturing process. In the industry chain, mature suppliers of plug-in touch control include Taiwan TPK and domestic manufacturer OFILM.

(3) Cover layer: The CPI film cover supplier of Samsung Galaxy Fold is Japanese manufacturer Sumitomo Chemical, and other mature suppliers in the industry chain are Korea Kolon Industries and Korea SKC. The domestic manufacturer Xin Lun Technology also has a related layout.

(4) OCA optical adhesive: Samsung Galaxy Fold's OCA optical adhesive supplier is its own SDI, and other mature suppliers in the industry chain include 3M in the United States and Mitsubishi in Japan. The domestic manufacturer Xin Lun Technology also has a related layout.

(5) Polarizer: The OCA optical adhesive supplier for Samsung Galaxy Fold is Nitto Denko, and the main one with production capacity in the industry chain is Japan’s Sumitomo Chemical. Domestic related enterprises are Sanli Spectrum.

(6) Structural parts: The folding hinge supplier of Samsung Galaxy Fold is South Korea’s KHVatec, and domestic related companies include Changying Precision and Yi’an Technology.

related news

Whether the folding screen mobile phone is an outlet or a gimmick is still controversial in the industry

Folding screen mobile phone: tuyere or gimmick? Folding screen mobile phone is popular. Samsung and Huawei released Galaxy Fold and Mate X in less than 4 days. Nubia, Xiaomi, OPPO and many other manufacturers have released mass-produced folding screen mobile phones or concept machines. The black technology of folding is amazing, and 2019 is called the first year of folding screen mobile phone applications in the industry. However, whether the folding screen mobile phone is an outlet or a gimmick is still controversial in the industry, and there is still a long way to go before the technology enters the homes of ordinary people.

The black technology behind folding

"Fold up for a phone, unfold for a tablet". Folding screen phones have attracted people's attention as soon as they are unveiled, the most notable of which are Huawei Mate X and Samsung Galaxy Fold. The biggest difference between the two is in the design concept of the folding method, which adopts the outer folding and inner folding design respectively. At present, the folding methods of folding screen mobile phones mainly include inward folding, outer folding, three-folding, and downward folding, each of which has advantages and disadvantages.

The most interesting core components of folding screen mobile phones are OLED flexible screens and hinges. Cui Zhen, a senior retrieval analyst at Beijing Chaofan Intellectual Property Management Consulting Co., Ltd., said in an interview with a reporter from China Intellectual Property News that compared with traditional LCD (liquid crystal display), OLED (organic light-emitting diode) has the property of automatic light-emitting, and consumes less energy. Less, wider vision, higher imaging quality, organic materials make the screen thinner and lighter, flexible display. OLED is divided into PMOLED (Passive Matrix Organic Light Emitting Diode) display technology and AMOLED (Active Matrix Organic Light Emitting Diode), the latter represents the mainstream direction of the industry. Both Huawei and Samsung folding screen mobile phones use flexible AMOLED screens.

However, the flexible OLED screen itself brings many technical challenges, including stack structure design, thin film packaging technology, etc. Ke Xiaopeng, general manager of the Intellectual Property Center of Visionox Technology Co., Ltd., introduced that the flexible OLED screen has a multi-layer structure and will be subjected to stress during folding. It needs to be balanced by the design of a neutral layer; if the screen cannot be isolated from water and oxygen, it will accelerate Aging, it is necessary to improve the packaging technology to extend the life of the screen; at the same time, it is also necessary to work with upstream and downstream to solve many problems such as hinge design and cover performance.

Another major difficulty in folding screen phones is the hinge at the bend, and hinge technology is essential to achieve perfect folding. In the folding area, both Huawei and Samsung have adopted a hinge structure to enhance the stability of bending. "The degree of fit, folding thickness, and folding life of the folding screen are closely related to the hinge. The hinge can effectively prevent the screen from being damaged by excessive distortion, and can also make the screen as perfect as possible to close and flatten out. If the hinge technology fails to meet expectations, it will make The screen is irreversibly damaged, which directly affects the service life." Ke Xiaopeng explained.

In addition, "the touch control of folding screen mobile phones is also an important technical theme for manufacturers to deploy patents." Liu Lin, an examiner of the Electrical Invention Examination Department of the Patent Office of the State Intellectual Property Office, introduced that touch technology mainly involves bending detection, screen area segmentation and display. , touch operation, etc., due to the flexible control method of the flexible screen, the touch technology of the folding screen mobile phone shows a variety, and the key research direction of the technology is the display and touch after folding.

A new vision for the future of mobile phones

Global smartphone market shipments declined for the first time since the fourth quarter of 2017, and have now declined for five consecutive quarters. "Major mobile phone manufacturers are trying to seize the innovative high ground and attract consumers' attention through the release of folding screen mobile phones, thereby triggering a new wave of smartphone revolution." Dong Xinrui, director of Luhao Group, believes that as for whether folding screen mobile phones are in the market or not Just need, as long as the manufacturer provides consumers with innovative product solutions, and at the same time meets the requirements of convenience, speed, and comfort, then it will be judged by time and the market.

The relevant person in charge of Huawei's consumer business told reporters that the innovation of the form of folding screen mobile phones is an inevitable trend of innovation and development in the industry. In the current environment of constantly escalating consumer demand, the large screen, differentiation and new interactive experience brought by folding will become the new trend. Gao Dongzhen, president of Samsung Electronics' mobile communications department, also declared at the press conference, "I'm sure everyone will need a foldable smartphone in the future."

"The folding screen can greatly expand the display area, which is not only full of novelty in appearance, but also brings a better user experience to users. From the heated discussion caused by the rush to release folding screen mobile phones, it can be foreseen that its market prospect is broad." Liu Lynn said.

"From the market reaction, the prevalence of full-screen displays shows people's demand for large-screen portability. From this, it can be judged that folding-screen mobile phones have huge market prospects." Ke Xiaopeng said that the current development of folding-screen mobile phones has just begun. It still takes time to improve. Folding screens may be a new stage in the development of screens. In the future, there may be more flexible screen mobile phones in various forms, and the era of flexible screens with arbitrary bending will soon come.

Cold thinking after the boom

However, at present, for folding screen mobile phones, some people question whether it is a "PPT product", "folding for folding", "doubtful in use value" and "mass production is not good enough". Dong Xinrui believes that the launch of folding screen mobile phones is a progress in technology and application, but there are still many challenges and uncertainties before the real marketization. Li Junhui, a special researcher at the Intellectual Property Research Center of China University of Political Science and Law, also said that in order to shatter the voices of various doubts on folding screen mobile phones, in the final analysis, mobile phone manufacturers still need to make major breakthroughs at the application level or system level.

From the product itself, the scratch resistance, service life and battery life of folding screen mobile phones have attracted much attention from the outside world. "The development direction of folding screen mobile phones in the future will be thin, wearable, and popularized." Liu Lin pointed out that hinges and other structures have extremely high requirements on the level of industrial design, and at the same time, they must reduce the volume of the structure and prolong the service life. , Reduce manufacturing costs, and the requirements for processing and manufacturing are also very high. In addition, smooth touch experience, battery life, etc. are the focus of future technological improvements.

In the opinion of Feng Ying, director of OPPO's intellectual property department, whether the folding screen mobile phone market has a future depends on whether the mobile phone solves the pain points of current consumers or improves the interaction and experience of consumers. Ke Xiaopeng also believes that after the realization of the folding technology, application adaptation and user experience will be difficult.

The staggering prices are also deterring consumers. "The high price of folding screen mobile phones is due to the high cost." Cui Zhen said that folding screens are the most expensive components in mobile phones. At present, there are not many companies in the world that can produce flexible OLEDs, including South Korea's Samsung, LG, and China. BOE, Visionox, Huaxing Optoelectronics and Tianma etc.

"The high cost is mainly due to the low yield rate of flexible screens and the limited scale of mass production. Whether the folding screen can be marketed is also an important step in determining its future development trend." Ke Xiaopeng said that because the folding screen needs to achieve dynamic folding at least 200,000 times , The requirements for materials and laminated structures are very high. In addition, high material costs, high process complexity, and long equipment debugging cycles all affect the yield and mass production of flexible OLEDs.

Although there are many doubts, mobile phone manufacturers are full of confidence. Samsung said that it is ready for mass production and is expected to supply at least 1 million units. Huawei also said that the Mate X is a mass production machine, not a concept machine, and is ready to challenge more than 100,000 units per month. According to the "Blue Book of China's New Display Industry (2017-2018)", the global foldable display AMOLED panel capacity growth rate is expected to be 28.1% in 2019; among them, China's growth rate is expected to be 39.4%, and the penetration rate is expected to exceed 50%. According to IHS Markit, shipments of foldable AMOLED panels are expected to reach 50 million units for the first time in 2025.