Comparison of CPI and UTG as Folding Lid Materials

Date:

2020-11-02

In 2019, except for ZTE's nubia α, almost all brands chose CPI as the foldable cover because of its better folding performance. At the time, CPI was the mainstream foldable cover material, but it wasn't perfect. CPI is used as a cover material because of its good folding properties, but it is not without its drawbacks. It is soft, wrinkle-prone, scratch-resistant, and has a plastic feel. The figure below shows the flaws of CPI.

"CPI and UTG have their own advantages and disadvantages, and it is difficult for both materials to be the best choice for foldable covers.

Note: The information in the text is only for sharing and communication channels

In 2019, except for ZTE's nubia α, almost all brands chose CPI as the foldable cover because of its better folding performance. At the time, CPI was the mainstream foldable cover material, but it wasn't perfect. CPI is used as a cover material because of its good folding properties, but it is not without its drawbacks. It is soft, wrinkle-prone, scratch-resistant, and has a plastic feel. The figure below shows the flaws of CPI.

Starting in 2020, brands will begin to use UTG instead of CPI. Samsung Galaxy Z Flip first attempt. According to Omdia's research, the Samsung Galaxy Z Fold2 will also be the next product to use UTG. Omdia's analysis suggests that Huawei and other brands are likely to follow.

SCHOTT was the first company to mass-produce UTG. Its Xensation Flex is confirmed for the Samsung Galaxy Z Flip. It is a direct thermoformed ultra-thin aluminosilicate glass with excellent ion exchange properties that enables chemical strengthening. In addition, it has high rigidity and small bending radius after chemical strengthening; it also has good transparency and light transmittance.

Comparison of CPI and UTG

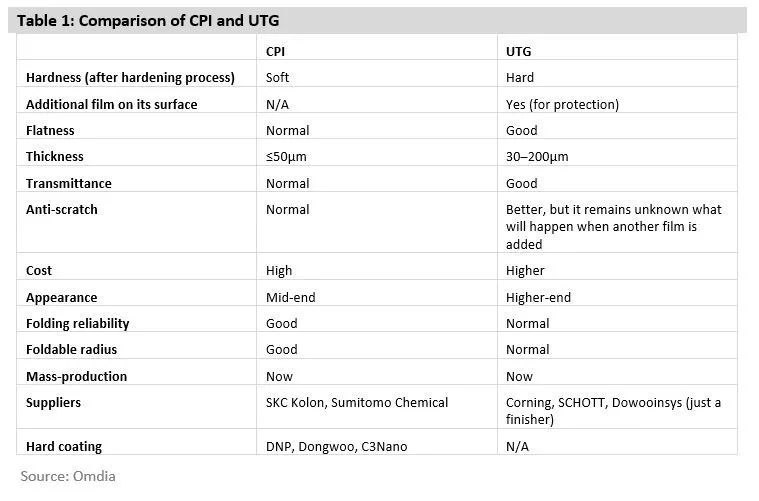

CPI has good bending properties, but its optical properties and scratch resistance are slightly insufficient, so a hard coat must be sputtered on the CPI.

Although UTG has good hardness, its impact resistance is still insufficient. It shatters easily under strong impact, so it is still not feasible to use it as the first surface of the foldable cover, and a protective film must be pasted on it.

However, when the protective film is applied to the UTG, a crease appears as shown in the picture below.

The long-term development direction of foldable covers

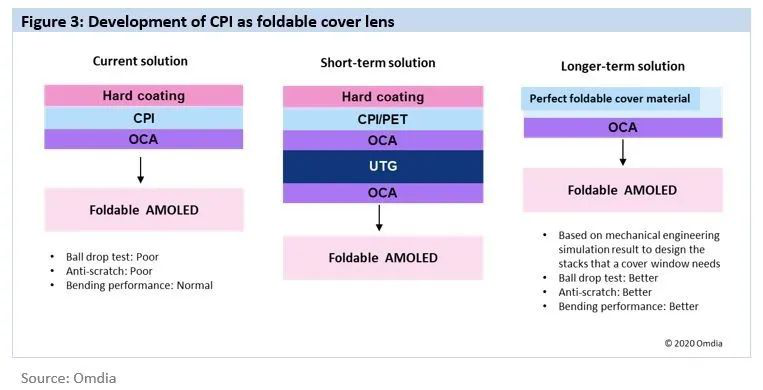

CPI and UTG have their own advantages and disadvantages, and it is difficult for both materials to be the best choice for foldable covers. Currently, the cooperation of the two materials is a viable solution. However, this composite material (pictured below) complicates the construction of the foldable cover. It becomes a sandwich structure and is not conducive to repeated bending.

Omdia believes that in the long run, it is still necessary to make improvements and upgrades from the material side, and it is necessary to develop new materials to replace CPI or UTG. The development of foldable display products must be based on the simplified structure, and the complex stack structure (sandwich) will not be the final solution for the foldable cover. It will also take time for companies in the industry to develop the perfect foldable cover material.